Sterling Machinery Exchange is proud to announce that we are the only place other than Cincinnati Inc. Headquarters (Located in Cincinnati, OH) for demonstration, training, and sales of prestigious Cincinnati Press Brakes, Shears, Lasers, Powder Presses and 3D Printing Machines in the world.

Cincinnati Inc. is one of the most illustrious and trusted companies manufacturing machinery today. With over 100 years of experience, Cincinnati incorporated focuses on Innovation, Endurance and Performance. Sterling Machinery Exchange has been at the forefront of new technology, from state of the art new machinery, to great deals and amazing finds on used machinery for over 60 years.

Call or Visit Sterling Machinery Exchange to trade in your older equipment and upgrade to a top-of-the-line Cincinnati press brake, Shear, Laser or 3D printer today 626-444-0311 !!

Check out our Brand New Cincinnati machines

This new technology uses servos to power the ram. This allows for a super high repeatability of ±0.0002” with repeatability day in and day out. It is completely electric and when it is between moves it is silent. The Goform is the perfect solution for small parts up to 1/4” thick and weigh less than 50 lbs. It is a small low profile machine that is built ergonomically for a user to comfortably sit or stand at the machine. The Cincinnati Goform Electric Press Brake has a electro-mechanical drive with satellite roller screws. This machine also has one of the largest strokes available with a 10” stroke and 17” open height compared to only 4” with other competitors brakes.Tooling, Tooling, Tooling, one of the best things about this brake is its adaptability of the tooling you are able to run with it. US Tooling, US self seating, Wila, Trumpf and European is all acceptable tooling for the Goform.The backgauge is a TRUE 6-axis gauge that moves at a incredible speed of 3,000 IPM. The Goform is also designed to be movable using a forklift to allow for easy work flow.

The Cincinnati Baseform comes with all the basic options and is increasingly the fastest growing brake on the market today, is the Cincinnati Baseform CNC Press Brake. This brake has a very competitive price structure compared to other manufacturers in the New CNC Press Brake Marketplace, such as Accurpress, JMT, Trumpf, Amada, Pacific and other similar high quality CNC Machines. It has accuracy repeatability of ± 0.0004”. Baseform is a production machine with limited customizable options opposed to a Proform, Maxform, Autoform or Goform. Baseform comes with a 3 axis or 4 axis CNC Cincinnati Touchscreen control, which is the same control across the board on the Cincinnati CNC Press Brake line. This makes it easier to step into other Cincinnati press brakes as your machinery needs increase, to a machine with larger stroke or other CNC capabilities. Another great option for your older Cincinnati brakes, is that you can upgrade your existing 1990’s CBII, FMII or AF to the same control and have 100% commonality of controls including tool libraries and program files.

The Cincinnati Proform+ is one of Cincinnati’s most popular machine on the market today. It is a heavy duty general purpose machine to get the job done quickly and accurately! The Proform+ can be customized to include extra stroke, special horns for the aircraft industry and up to a 8 axis CNC Control. Also optional on the Proform+ is auto crowning, power clamping, multiple tool options to accommodate USA, European, Wila and Wilson Tooling. All with a repeatability of ±0.0004”.

The most customizable CNC press brake made by Cincinnati Inc. is a Cincinnati Autoform+. Cincinnati Inc. can install Special Horns on the machine for aircraft industry forming or other special forming and punching operations. Also included in the Autoform+ is Standard DTC (Dynamic Thickness Compensation which allows the brake to automatically measure the thickness of the material as it is bending to calculate the changes in reversal for air bending). Autoform+ that has ±0.0004” repeatability rate. How long of a Stroke do you need? Just let us know and Cincinnati can build to order. If you are looking for a Tandem Press Brake for long pieces Autoform+ is your best choice!

If you are looking for even more capabilities by way of ultra high speed as well as repeatability ±0.0002”, please inquire about a MaxForm Cincinnati Press Brake. Cincinnati Maxform Press Brakes can be customized to accomodate larger stroke, auto crowning, hydraulic clamping, standard DTC (Dynamic Thickness Compensation which allows the brake to automatically measure the thickness of the material as it is bending to calculate the changes in reversal for air bending), Heavy Duty Backgauges and more! It comes standard with a 5-axis gauge with optional 6-axis linear motor drive gauge allowing for the fastest CNC system on the market!

CINCINNATI Hydraulic Shears provide power and high value for low-cost, dependable shearing and are available in standard capacities for cutting 10 gauge up to 3/4" metal plate.All steel interlocked construction improves reliability by eliminating stresses inherent with welded joints. Clevis mounted "swivel bearings" allows unrestricted movement of cylinders and eliminates oil leakage caused by binding or twisting. Twin precision lead screws are mounted in a heavy duty steel frame to maintain precise backgage alignment. Shock absorbing springs further protect position accuracy and compensate for material impact against the gage surface. The backgage is easily set parallel to the lower knife by micrometer adjusting nuts at the end of the guides. Electronically variable cut length results in fast stroking speeds. Machine cycling is initiated using a convenient footswitch. Quick response-time valves with microprocessor control are key reasons for faster processing and higher productivity. Unique knife removal fixture reduces knife rotation or changing time by 40 percent with less physical effort. Low profile, modern, compact design enables operator to maintain complete control of material whether processing thick or thin, narrow or wide sheets.

CINCINNATI Mechanical Shears are available in standard capacities from ¼" to ½" mild steel. This power squaring shear is designed to make the maximum number of cuts per hour. Many options and accessories are available.

Portable machine controls are pedestal mounted for easy, convenient operation. The power-operated backgage with digital control enables accurate setups to be made quickly.

Electronically variable rake and cut length result in fast stroking speeds. Machine cycling is initiated using a convenient footswitch. Quick response-time valves with microprocessor control provide faster processing and higher productivity.

Material positioning occurs as the pre-programmed microcomputer control properly positions the backgage. The LED readout of actual gage position in .001" or .01 millimeters allows the operator to quickly verify the gage position. Twin precision lead screws are mounted in a heavy-duty steel frame to maintain precise backgage alignment. Shock absorbing springs further protect position accuracy and compensate for material impact against the gage surface.

Final blank accuracy is maintained within tight tolerances cut after cut, using the programmable microcomputer gage control which automatically positions the backgage within + .005".

High-pressure hydraulic holddowns clamp material securely with tons of force to prevent movement during cutting. Holddowns can be activated independent of the knife permitting verification of material position. This feature will improve accuracy when cutting to a scribed line.

Long life on all wearing surfaces is further assured by centralized automatic lubrication, delivering oil to all necessary lubrication points.

Protection of the precision backgage against plate impact is provided by shock absorbing springs.

Shielding the backgage cross shaft from damage by lift trucks and crane hooks is assured by locating it forward of the ram brace.

Blank accuracy and parallelism are maintained by precise calibration of micrometer adjusting nuts with graduations of .001" on each backgage screw.

Maximum reliability and ease of maintenance are assured by the unique hydraulic manifold block on which all valves are mounted with flanged fittings and "O' ring seals. This eliminates the majority of piping and fittings plaguing maintenance personnel on conventional hydraulic shears.

Trouble free operation is maintained by self-aligning clevis mounted cylinders, which eliminate binding of packing and minimize oil leakage.

CINCINNATI CV Series Shear Conveyors can be optionally added to new CINCINNATI HS, SE, and G Series shears as well as existing CINCINNATI hydraulic and mechanical shears. One operator performs the normal function of feeding material into your shear while stacking and scrap separation are accomplished simultaneously. Where secondary shearing is required the blanks can be brought to the front of the shear in a neat stack for processing into finished blanks. Because stacking is now an integral part of the shearing process, your shear is available for a greater number of hours each day to produce blanks. Material is handled only when feeding it into the shear.There is not requirement for the operator to pick up the tons of finished blanks which are produced each day. Sturdy material supports guide the material over rollers from the shear table, minimizing sheet sag and allowing the material to be firmly positioned against the backgage. They retract quickly when the shear is cycled allowing the sheared blank to fall onto the conveyor belts. Deep back pieces, up to the limit of the backgage, contact the probes on the shear's backgage. You can gage ferrous and non-ferrous materials in a wide range of gauges with equal ease and accuracy using the material supports.

The productivity comes from overcoming the limitations inherent to conventional lasers. Straight line cutting speed is maximized using a resonator with 4000 watts of CW power, beam enhancement optics and 400 PSI assist gas capabilities. The motion system provides high accelerations and accuracies through the use of linear motors, linear encoders and advanced aerospace composite construction. Maximum positioning speed of the cutting head is 12,020 inches per minute. Dual pallets permit the operator to simultaneously unload parts and load new material on one pallet while the laser is cutting on the other pallet. The conveniently located control, with 15” color LCD touch screen display and full sized standard keyboard, provides the operator with a user-friendly Human Machine Interface (HMI) with nesting software. Dynamic Power Control (DPC) automatically maintains the proper relationship between laser power and the instantaneous feed rate, which is critical for high part accuracy and quality edge condition. The Autofocus laser cutting head automatically adjusts the focus to .001”. A self-aligning lens holder, nozzle tip assembly and laser head construction permits the processing of different materials with minimal set up.

The CL-800 controls Human Machine Interface (HMI) is easily understood and intuitive in its use enabling operators to produce good parts independently. In a work environment where operators often switch from machine to machine it is key to have a control where one can be cutting parts quickly, fast and accurately. The CL-800 control excels in this area. The CINCINNATI HMI has a touch screen display, easy to understand buttons and a full size keyboard. Using the Windows Operating System, the operator feels right at home. The HMI is located where the operator can easily monitor the cutting process while loading and unloading the CL-800. Rather than using cumbersome tech tables, the CL-800 uses Dynamic Power Control (DPC), which computes optimum power and the fastest possible cutting speed for any material on the fly.

The CL-900 Series Fiber Laser System offers high speed cutting on thinner materials and lower operating costs. The CL-900 controls Human Machine Interface (HMI) is easily understood and intuitive in its use enabling operators to produce good parts independently. In a work environment where operators often switch from machine to machine it is key to have a control where one can be cutting parts quickly, fast and accurately. The CL-900 control excels in this area. The CINCINNATI HMI has a touch screen display, easy to understand buttons and a full size keyboard. Using the Windows Operating System, the operator feels right at home. A web cam is available for easy monitoring of the cutting process. Rather than using cumbersome tech tables, the CL-900 uses Dynamic Power Control (DPC), which computes optimum power and the fastest possible cutting speed for any material on the fly.

Learn more about CINCINNATI’s Automation Systems which include the Modular Material Handling System 100 (MMHS-100), Compact Tower Modular Material Handling System (CTMMHS-200) and Sorting Modular Material Handing System (SORTMMHS-300).

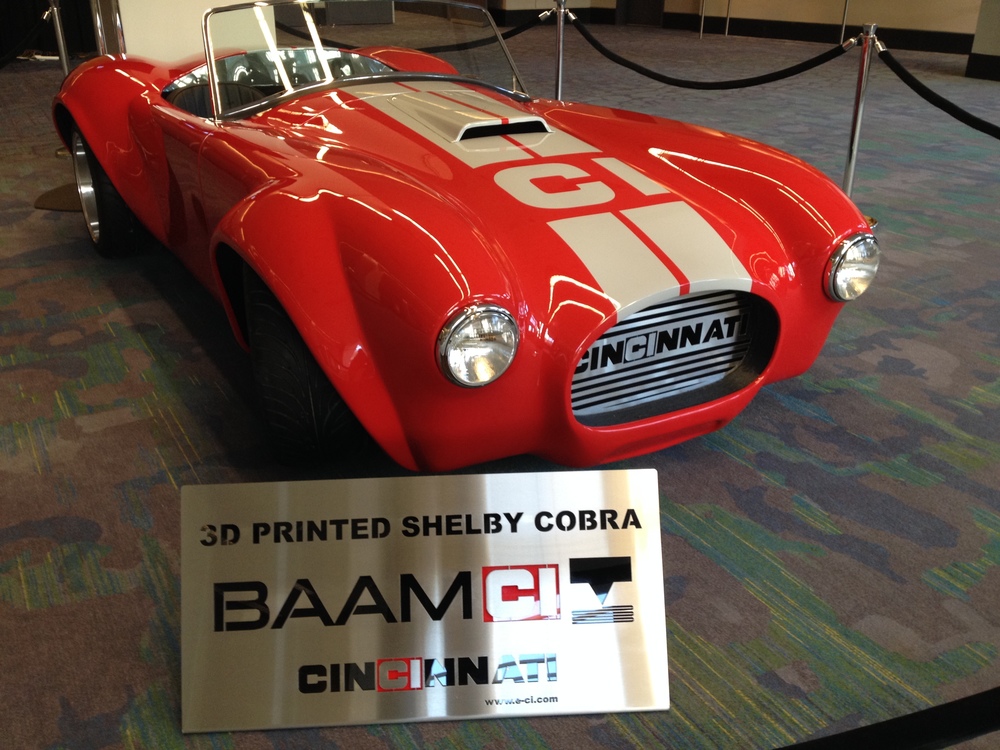

3D printing or Additive manufacturing is a process of making a three-dimensional solid object of virtually any shape from a digital model. 3D printing is achieved using an additive process, where successive layers of material are laid down in different shapes. 3D printing is also considered distinct from traditional machining techniques, which mostly rely on the removal of material by methods such as cutting or drilling (subtractive processes).

.png)

Last Updated :Fri, Dec 19, 2025